nsenterprises789@gmail.com - GST NO. : 27AJVPS4739G1ZF

| Business Type | Manufacturer, Exporter, Supplier |

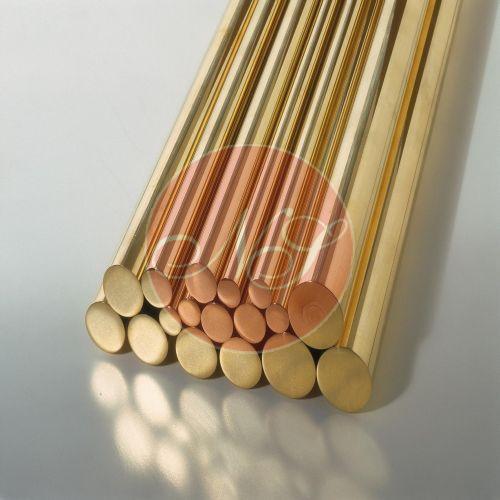

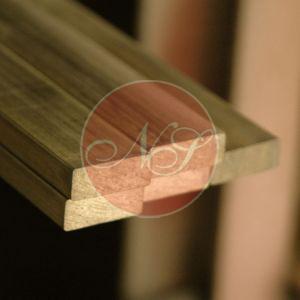

| Material | C63000 Aluminium Bronze |

| Form | Bar |

| Thickness Range | 5mm To 50mm |

| Click to view more | |

Product Details

Aluminum Bronze Products

Precision Engineered by N S Enterprises – Experts in Non-Ferrous Alloys

Leveraging our domain expertise, we offer an exceptional range of Aluminum Bronze Products, meticulously crafted by our skilled workforce in adherence to stringent industry quality standards. Aluminum Bronze, a copper-based alloy with aluminum as the primary alloying element, is renowned for its superior strength, dimensional accuracy, corrosion resistance, and long-term durability.

At N S Enterprises, we specialize in manufacturing and supplying a diverse array of non-ferrous products, including:

-

Aluminum Bronze Products

-

Lead Tin Bronze Products

-

Phosphor Bronze Products

-

Gun Metal Products

-

Tiger Bronze Products

-

Brass Products

Aluminum bronze products are widely used across demanding industries due to their unmatched performance in challenging environments. Typical applications include:

-

Marine hardware

-

Pump and valve components (especially for seawater and industrial fluids)

-

Shafts and heavy-duty sleeve bearings

-

Machine tool ways and motion assemblies

-

Environments with sour mine waters, non-oxidizing acids, and corrosive fluids

These castings offer excellent corrosion resistance, high mechanical strength, outstanding toughness, and exceptional wear resistance, making them suitable for both structural and dynamic components. Their favorable casting and welding characteristics further enhance their versatility.

Key Features-

Superior Strength & Wear Resistance: A high-strength alternative to brass, aluminum bronze offers improved durability in high-friction applications.

-

Excellent Corrosion Resistance: Performs exceptionally in marine and chemically aggressive environments.

-

Highly Polishable Surface: Delivers a refined finish and aesthetic appeal.

-

Heat-Treatable for Enhanced Performance: Mechanical properties can be further improved through controlled heat treatment.

-

Cleaner Composition: Free from lead with controlled trace elements, ensuring safer and more stable performance.

-

Friction & Motion Applications: Ideal for sliding components, wear parts, and applications with movement-induced stress.

-

Problem Solver: Recommended for tackling cavitation, galling, tooth flank damage, and surface degradation in stainless steel systems.

Conclusion

Aluminum bronzes are a part of the copper alloy family, where aluminum acts as the principal alloying element. Their unique properties arise from the synergy between copper and aluminum, fused through rigorous, controlled melting and casting processes. As a result, Aluminum Bronze is a preferred choice for applications requiring reliability, strength, and resistance to harsh conditions.